- Cur síos

- Fiosrúchán

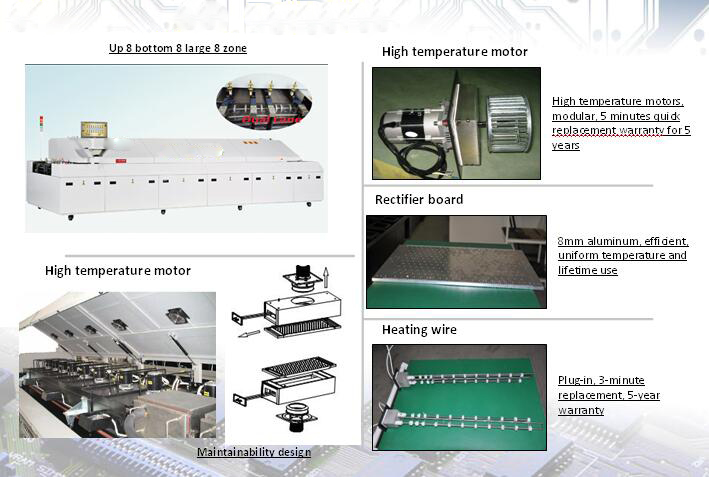

Reflow soldering oven introduction:

Reflow soldering oven is used after chip mounter for SMT assembly line.

Sonraíocht Theicniúil:

| Teas chuid |

Toise Lasmuigh(L * W * H.) | 4500x1250x1520mm | ||||||

| Meáchan | Approx.2250KG | |||||||

| Líon na gCriosanna Teasa | Suas8 / Bun8 | |||||||

| Crios fuaraithe | by cooling fan | |||||||

| Fad Criosanna Teasa | 2800mm | |||||||

| Smacht

Córas |

Soláthar Leictreonach Riachtanach | 3céim,380V 50 / 60Hz (rogha: 3céim,220V 50 / 60Hz) | ||||||

| Cumhacht Chun Te suas | 22KW | |||||||

| Ídiú cumhachta | 7KW | |||||||

| Am Téimh | Thart ar 20 nóiméad | |||||||

| Teocht. Raon Socraithe | Temp Seomra. — 300℃ | |||||||

| Córas rialaithe | PC + PLC | |||||||

| Beachtas Rialaithe Teochta | ± 1.0 ℃ | |||||||

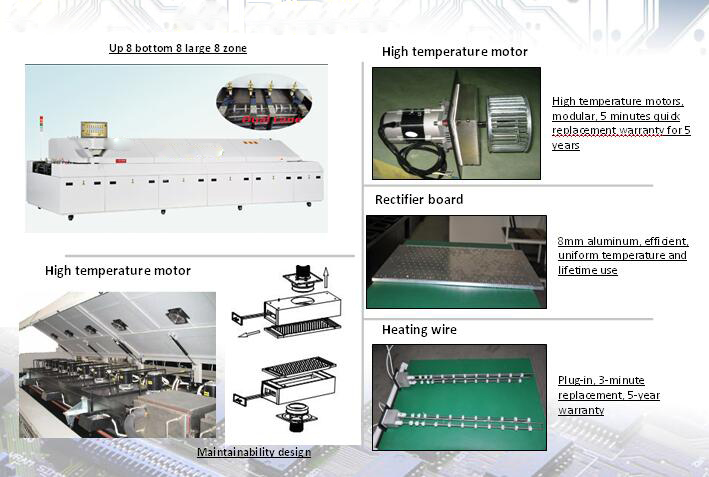

| Eilimint Téimh | Eilimintí Téimh Speisialta don Saol Fada | |||||||

| Eilimint Comaitéireachta | Pláta Alloy Alúmanam | |||||||

| Aláram Neamhghnách | Teocht neamhghnácha (Breise-ard / Teocht Breise-íseal.) | |||||||

| Aláram Báite an Bhoird | Téamh Buí; Glas-Gnáth; Dearg-Neamhghnách | |||||||

| Iompróir Córas |

Cainníocht Lána | 1 | ||||||

| Uasmhéid Leithead PCB | mogalra:400mm,rail:300mm | |||||||

| Airde na gcomhpháirteanna | Is é 25mm airde Barr / Bun an PCB | |||||||

| Treo Converyor | Ó chlé go R.; R go L. | |||||||

| Taobh Iarnróid Seasta | Iarnród Tosaigh Seasta(Rogha:Iarnród Cúil Seasta) | |||||||

| Gníomhaire Tarchurtha PCB | Aer-Reflow = Slabhra + Mogalra , N2-Reflow = Slabhra(Is é mogalra an rogha) |

|||||||

| Tacaíocht Ionad(Roghnach) | Cosc a chur ar PCB a bheith dífhoirmithe mar gheall ar PCB ró-leathan nó an chomhpháirt ró-throm |

|||||||

| Airde an Chonraitheora | 900+/-20mm | |||||||

| Luas Luais Converyor | 300~ 2000mm / nóim | |||||||

| Bealaithe féin-sní isteach | Caighdeán | |||||||

| Teocht. Sliotán Teirmeachúpla | Caighdeán | |||||||

| Oscailt Hood Barr Tiomáinte | Caighdeán | |||||||

| Modh Fuarú | Aer Éigeantach (Caighdeán), Uisce-Uisce (Rogha) | |||||||

Gnéithe Táirge:

1. The brand computer + Siemens PLC intelligent control system, high precision temperature control is ± 1-2 ℃ (if the computer crash accident, and can realize off-line work, do not affect production) and to ensure that the control system is stable and reliable;

2. Windows operating interface, powerful, simple operation,

3. On the cylinder body open automatic lifting machinery, ensure safe and reliable;

4. Equipped with mesh belt tensioning device, transport smoothly and no shaking, deformation, ensure smooth PCB transport; Synchronous guide transmission mechanism (and automatic SMT machine online connection), ensure that guide adjustable wide precision and high service life;

5. Automatic control lubrication system, through the set come on time and fuel charge, automatic lubrication transmission chain;

6. All heating zone all by computer PID control (upper temperature zone and lower temperature zone implementation independent temperature control, can divide temperature area alone. Can open division heating, in order to reduce starting power);

7. Net/chain transmission by computer to carry out the whole closed loop control, can meet different kinds of PCB production at the same time

8.With fault sound and light alarm function;

9. With leakage protector, ensure that the operating personnel and control system security;

10.The built-in UPS and automatic delay shutdown system to guarantee the PCB and return welder in power or overheat not damaged;

11. The German ERSA world leading microcirculation heating mode, and the upper and lower independent air microcirculation system, temperature uniformity and thermal compensation high efficiency, high efficient supercharged accelerated air duct, greatly improve the circulating hot air flow, temperature quickly (about twenty minutes), thermal compensation for high efficiency, high temperature welding and curing;

12. The upper and lower every temperature zone with independent temperature inductive sensor, real-time monitoring and compensation every temperature zone temperature balance;

Tuilleadh pictiúr:

Product Details:

Nasc físe: