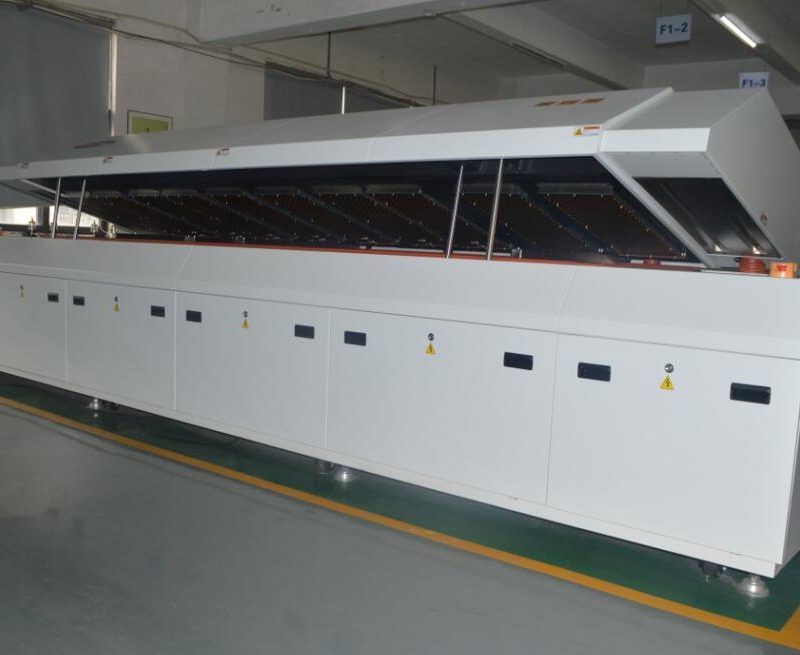

- JW-IR300C konforme deklaag genesingsoond

- JW-IR300C konforme deklaag genesingsoond

Economical reflow oven machine:

The economical reflow oven machine is used on small quantity production SMT assembly line or products that don’t need with high precision.

Tegniese spesifikasie:

| Handelsmerk | Jwyd | |

| JW-IR300C konforme deklaag genesingsoond | JW-8800 | |

| Heating system |

Heating zone | 8 zones |

| Heating zone length | 2800JW-IR300C konforme deklaag genesingsoond | |

| Cooling zone | 2 zones | |

| Max. JW-IR300C konforme deklaag genesingsoond | 400JW-IR300C konforme deklaag genesingsoond | |

| Rail adjustment range | 50~300mm | |

| Conveyor direction | L to R or R to L | |

| Fixation type of rail | front or rear | |

| Vervoerband hoogte | 900+/- 20JW-IR300C konforme deklaag genesingsoond | |

| Conveyor type | chain + mesh | |

| Conveyor speed | 0~2000mm/min | |

| Temperature control system |

Power | 3 phrase 5 wires (380V 60/60 HZ) |

| Start power consumption | 20~40 KW adjustable | |

| Operation power consumption | 10JW-IR300C konforme deklaag genesingsoond | |

| Heat up time | approx. 20 minutes | |

| Range of temperature control | Room temp:~350℃ | |

| Temperature control mode | PID&SSR | |

| Temperature control accuracy | ±1℃ | |

| Temperature distribution error | ±2℃ | |

| Abnormal alarm | alarms when temperature out of tolerance | |

| Machine size & weight |

Approx. weight | 1400kg |

| JW-IR300C konforme deklaag genesingsoond | 4200*900*1650 | |

JW-IR300C konforme deklaag genesingsoond:

1. The brand computer + Siemens PLC intelligent control system, high precision temperature control is ± 1-2 saam met ondersteunende stelsel om PCB-vervormde tempo te verminder (if the computer crash accident, and can realize off-line work, do not affect production) and to ensure that the control system is stable and reliable;

2. Windows operating interface, powerful, simple operation,

3. On the cylinder body open automatic lifting machinery, ensure safe and reliable;

4. Equipped with mesh belt tensioning device, transport smoothly and no shaking, deformation, ensure smooth PCB transport; Synchronous guide transmission mechanism (and automatic SMT machine online connection), ensure that guide adjustable wide precision and high service life;

5. Automatic control lubrication system, through the set come on time and fuel charge, automatic lubrication transmission chain;

6. All heating zone all by computer PID control (upper temperature zone and lower temperature zone implementation independent temperature control, can divide temperature area alone. Can open division heating, in order to reduce starting power);

7. Net/chain transmission by computer to carry out the whole closed loop control, can meet different kinds of PCB production at the same time

Meer foto's:

Economical SMT assembly line:

saam met ondersteunende stelsel om PCB-vervormde tempo te verminder:

saam met ondersteunende stelsel om PCB-vervormde tempo te verminder 2005,

saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder:saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,Taal,

saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,Taal,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,Voer kalibreerder ens.

saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder;

Video skakels: