- JW-608A automatyske PCB skonk cutter

- JW-608A automatyske PCB skonk cutter

PCB NG/OK unloader function:

The PCB NG/OK Unloader is used in SMT assembly line after AOI or other inspection machine that OK board is sent to one magzine,and NG board to another magzine.

Technyske spesifikaasje:

| Merk | JW-250 | JW-330 | JW-390 | JW-460 | ||||

| JW-608A automatyske PCB skonk cutter | 1700*750*1200JW-608A automatyske PCB skonk cutter | 1950*830*1200JW-608A automatyske PCB skonk cutter | 2210*920*120JW-608A automatyske PCB skonk cutter | 2210*990*1200 | ||||

| Magzine grutte | 355*320*563JW-608A automatyske PCB skonk cutter | 460x400x565 mm | 535*460*570JW-608A automatyske PCB skonk cutter | 535*530*570JW-608A automatyske PCB skonk cutter | ||||

| PCB Grutte | 50*50~350 * 250 mm | 50×50~ 455*330mm | 50*50~530*390mm | 50*50~530*460mm | ||||

| Lucht oanfier | 5kgf/cm2 | 5kgf/cm2 | 5kgf/cm2 | |||||

| Power voltage | AC220V 50/60HZ | AC220V 50/60HZ | AC220V 50/60HZ | |||||

| JW-608A automatyske PCB skonk cutter | 900± 20 mm | 900± 20 mm | 900± 20 mm | |||||

| PCB dikte | 0.4~8mm | 0.4~8mm | 0.4~8mm | |||||

| Ferfier rjochting | L oan R; R oan L | L oan R; R oan L | L oan R; R oan L | |||||

| Repeatabiliteit | 0/05JW-608A automatyske PCB skonk cutter | 0/05JW-608A automatyske PCB skonk cutter | 0/05JW-608A automatyske PCB skonk cutter | |||||

| JW-608A automatyske PCB skonk cutter | 130kg | 150kg | 150kg | |||||

JW-608A automatyske PCB skonk cutter:

1.Super aluminum frame,much more stable,direction from L to R or R to L.

2.Full color touch screen control with automatic alarm function,easy and convenient.

3.PLC control with Omron relay control,high performance.

4.Adopt imported roller screw and support for up and down system,no noise and shake.

5.Intelligent control system, built-in detailed fault retrieval function and safety detection system,

sound and light alarm when abnormal, and text prompt processing scheme

6.Each lift has three safety limits, which are safe and reliable.

7.Adopting 4 upper and lower cylinder clamp frames, stable and reliable, accurate board entry

8.Hand-cranked push rod cylinder widening system, convenient and fast

9.Up step can be set according to component height on the PCB.

Foardielen:

1.Team of after sale service engineer to better serve clients worldwide

2.Aluminum frame structure

3.Panasonic PLC + Folsleine kleur brûkerfreonlik touchscreen

4.Easy maintainence

5.SMEMA compatible

6.Rjochting:Left to right; right to left

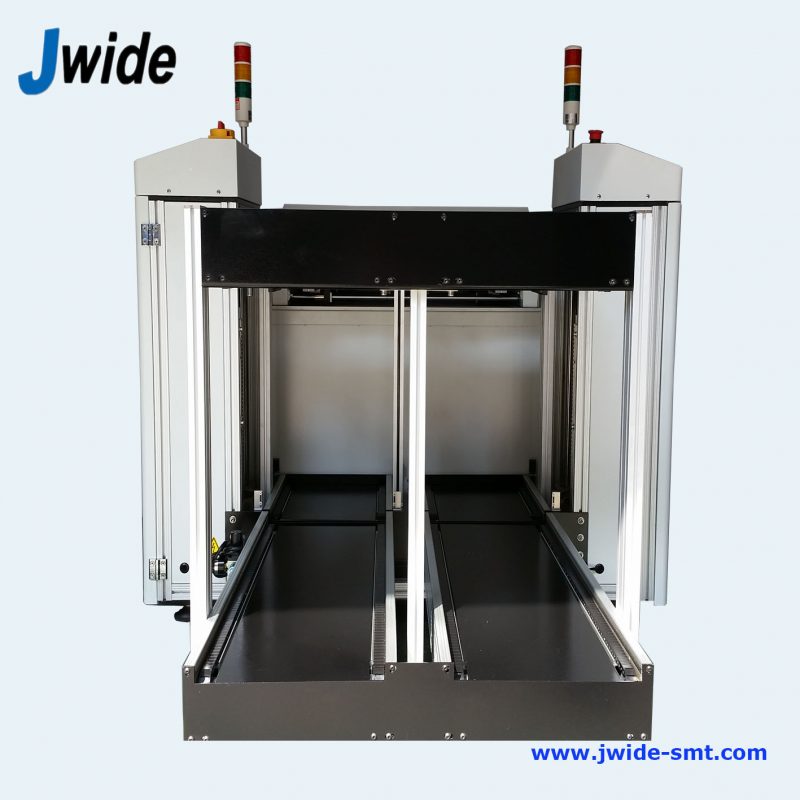

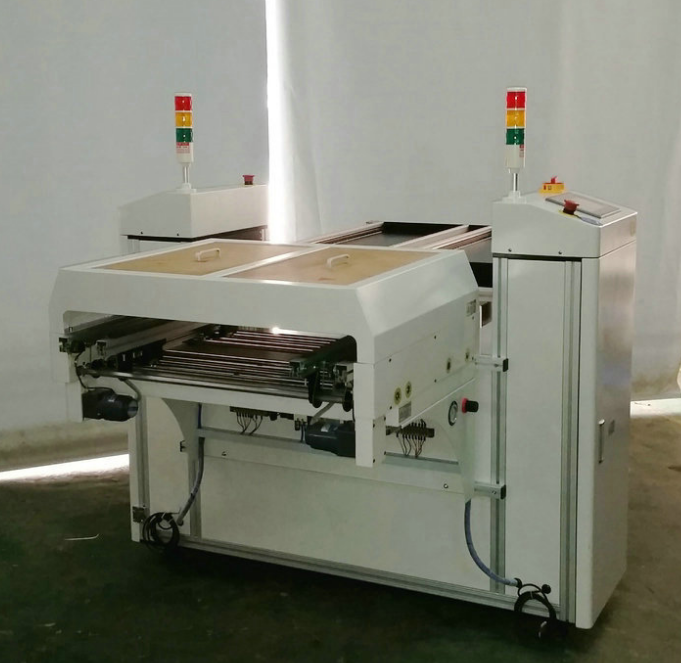

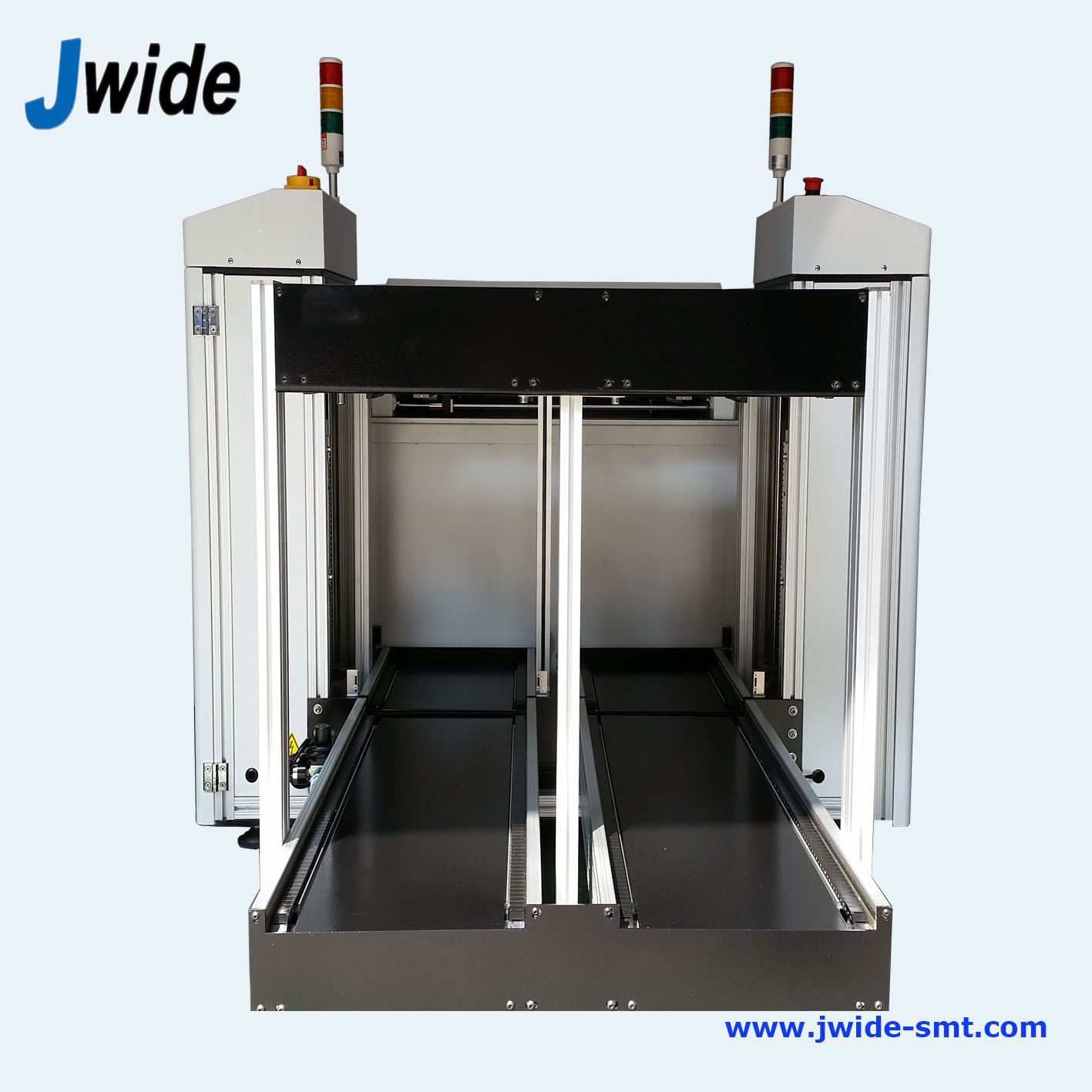

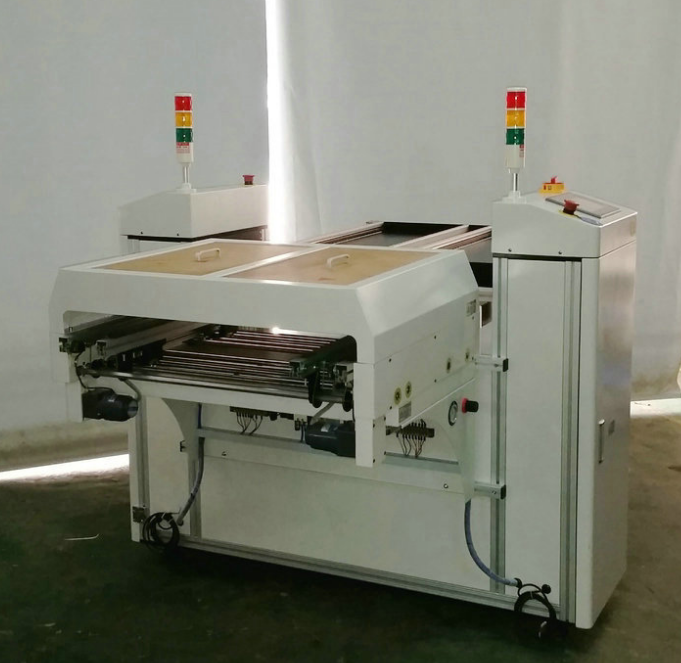

Pictures:

Video demonstraasje: