- JW-608A automatyske PCB skonk cutter

- Additional Information

- JW-608A automatyske PCB skonk cutter

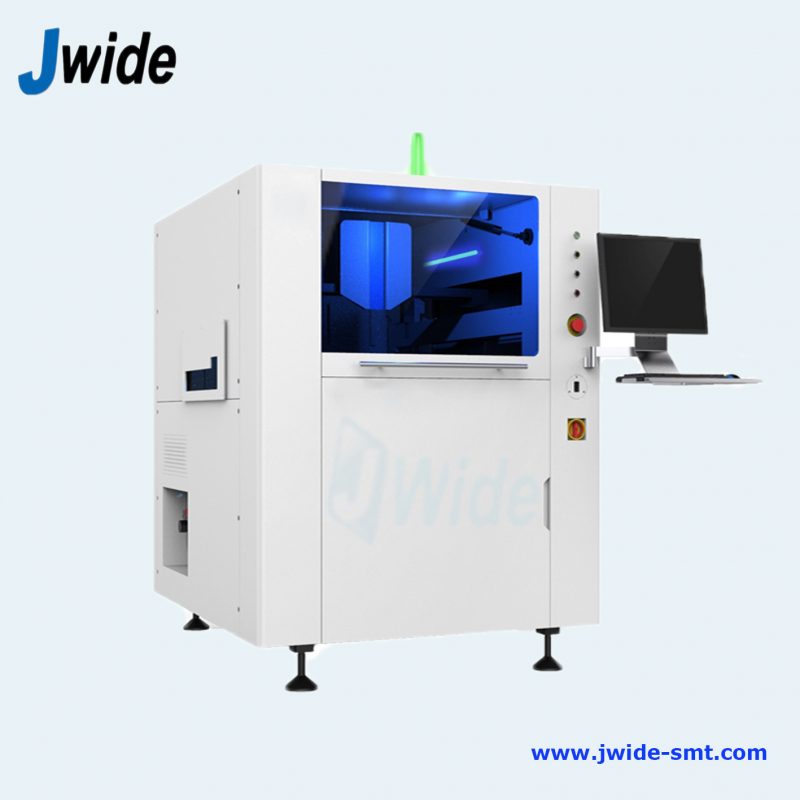

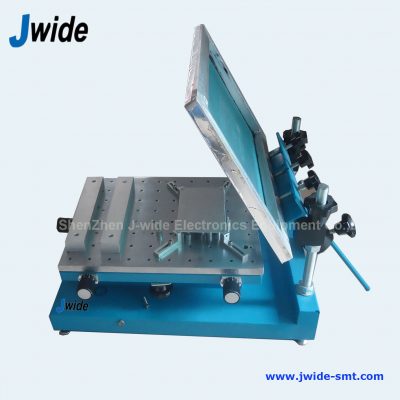

Automatic PCB stencil printer

The automatic PCB stencil priFnter is used to print solder paste onto circuit boards automatically to save labor cost and achieve full automation for SMT assembly line.It’s used after PCB loader machine.

Product specification:

| Merk | JW-GD450+ |

| Max.PCB size | 450*350JW-608A automatyske PCB skonk cutter |

| Min.PCB size | 50*50JW-608A automatyske PCB skonk cutter |

| Max. PCB gewicht | 6kg |

| PCB margin gap | configuration to 3mm |

| Transfer Speed | 1500mm/second(max.) |

| Transfer height from the ground | 900+/-40JW-608A automatyske PCB skonk cutter |

| Transfer guide rail direction | L oan R; R oan L |

| Transfer mode | One stage orbit |

| PCB support method | Magnetic thimble,equal high block,vacuum suction cavity |

| Printing head | Linear motor type close loop printing head |

| Stencil frame size | 370*470~737*737mm |

| Max.Printing area | 450*350JW-608A automatyske PCB skonk cutter |

| scraper type | steel scraper/rubber scraper |

| Scraper length | 220~500mm |

| Scraper height | 65+/-1JW-608A automatyske PCB skonk cutter |

| Scraper thickness | 0.25 diamond like carbon |

| printing speed | 0~200mmmm/second |

| printing pressure | 0.5~10kg |

| JW-608A automatyske PCB skonk cutter | AC 220V,50/60HZ,15A |

| External dimension | 1140*1400*1480JW-608A automatyske PCB skonk cutter |

| JW-608A automatyske PCB skonk cutter | approx.1000kg |

JW-608A automatyske PCB skonk cutter:

1.Special mathematical model, repeat accuracy ± 12.5 microns (± 0.0005 “) @ 6 σ, Cp ≥ 2.0.

2.Special high-rigidity UVW module drive mechanism and inverted triangle Z-axis lifting mechanism to effectively improve the stability of the platform adjustment.

3.under the fine adjustment to achieve ultra-fine transmission, the machine meets the requirements of higher precision printing.

4.Simple and reliable structure, easy to adjust, you can quickly achieve different thickness of the PCB board PIN pin height adjustment of the automatic adjustment.

4.Independent direct-coupled stepper motor control, built-in precision pressure control system, can accurately measure the original blade pressure value

5.The pressure of the scraper, the printing speed, the printing range are software adjustable, and provide customers with the A variety of stripping methods to adapt to different requirements of the PCB board.

6. Flat belt drive, can be programmed to achieve different transport speed and action; new concept guide, seamless transmission to ensure the reliability of PCB transport; adaptive PCB board thickness, process more Simple;

7.software adjustable pressure elastic side pressure, can be equipped with the bottom of the overall suction chamber vacuum, and the bottom of the local vacuum.

8.Automatic cleaning structure; high-power fan plus Venturi vacuum generator device vacuum; dry , wet ,vacuum three cleaning methods, and can choose any combination of free,

9.length Clean paper, easy to disassemble, save resources; soft wear-resistant rubber wipe board, clean thoroughly, easy to disassemble.

10.To achieve a variety of sizes (370mm x 470mm ~ 737 mm x 737 JW-608A automatyske PCB skonk cutter) of the network box printing, and can be achieved in the production process of rapid replacement models; Y to automatic positioning.

11.Using independent research and development of modular integrated circuits, safe, easy to repair; using the industry’s most advanced industrial control system, the machine can be modified in the process of moving parameters.

Video Link:

Additional Information

| JW-608A automatyske PCB skonk cutter | 270 kg |

|---|---|

| Dimensions | 96 x 81 x 173 cm |