- JW-IR300C konforme deklaag genesingsoond

- JW-IR300C konforme deklaag genesingsoond

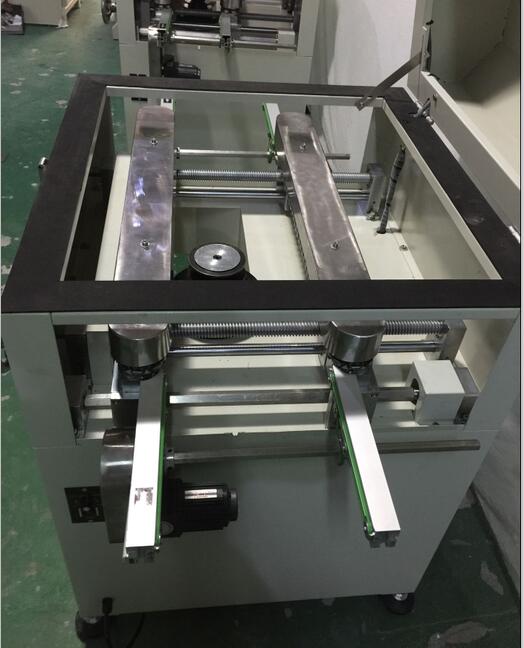

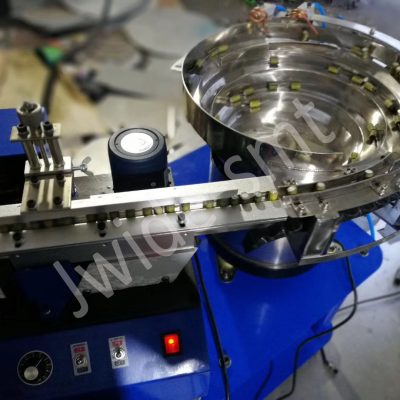

PCB leg cutter function:

PCB leg cutter is used to cut components long lead leg to shorter size so that it can work well in golf soldeersel.

Produk spesifikasie:

| MODEL | JW-608A PCB Leg cutter | |||||||

| JW-IR300C konforme deklaag genesingsoond | 1400*700*1050JW-IR300C konforme deklaag genesingsoond | |||||||

| PCB Width | 50~250 mm | |||||||

| Blade motor | 1P AC220V 50HZ | |||||||

| PCB rigting | L-R or R-L | |||||||

| Spoed | 0~2000mm/min | |||||||

| JW-IR300C konforme deklaag genesingsoond | 1P AC220V 50/60HZ 90W | |||||||

| JW-IR300C konforme deklaag genesingsoond | 1P AC220V 50/60HZ | |||||||

| Transport height | 750+/- 20JW-IR300C konforme deklaag genesingsoond | |||||||

| Bandmateriaal | ESD Belt | |||||||

| Gewig | Approx.145kg | |||||||

JW-IR300C konforme deklaag genesingsoond:

1.Three step designs(PCB Inputting,Leg cutting,PCB taking out),mainly consists of 3 separate power driver system,and 1 set width adjustment system;maklike operasie.

2.There is glass covered area on upper of machine to better monitor cutting process.

3.Front and rear conveyor set:Adopts Japanese geared motor and Dutch ESD belt conveyor,much more durable and electronic variable speed.

4.Main body:can choose single or double blade cutting,single or double independent power system according to PCB size,unique patented spring claws to confirm stable PCB cutting to effectively reduce PCB-lock and PCB -falling.

5.Can also used DIP process before wave solder,exist can be used as a conveyor between leg cutter and wave solder for buffer and make up components.(Long DIP process:PCB Leg cutter before wave solder).

6.Cutting blade assembled with Japanese imported high precision NSK gear to ensure low noise when high speed running,blade moving stably,less cutting effect attrition;and blade’s lifespan is 35.8% longer than other suppliers .

7.Blade power driving system adopts TaiWan DongYuan Motor and Suzuki triangle belt.No vibration and noise.

8.Machine is applicable for DIP process after or before wave solder.

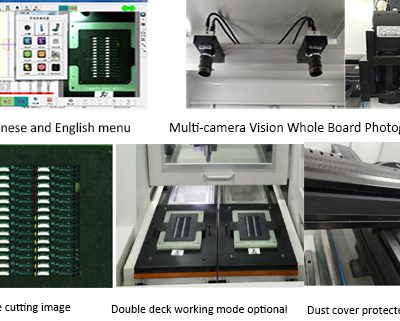

Meer foto's:

saam met ondersteunende stelsel om PCB-vervormde tempo te verminder:

saam met ondersteunende stelsel om PCB-vervormde tempo te verminder 2005,

saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder:saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,Taal,

saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,Taal,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder.

saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder;