- JW-IR300C konforme deklaag genesingsoond

- JW-IR300C konforme deklaag genesingsoond

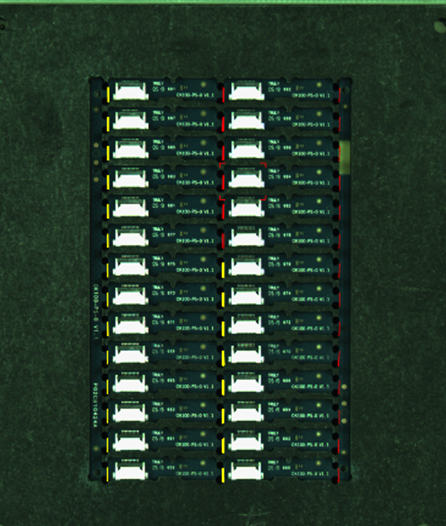

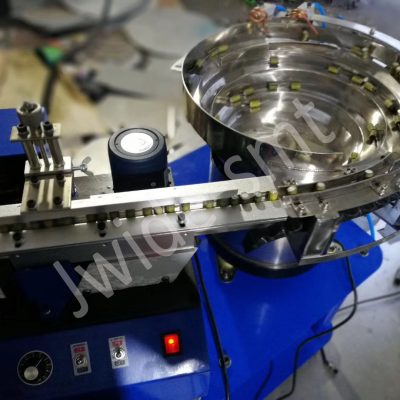

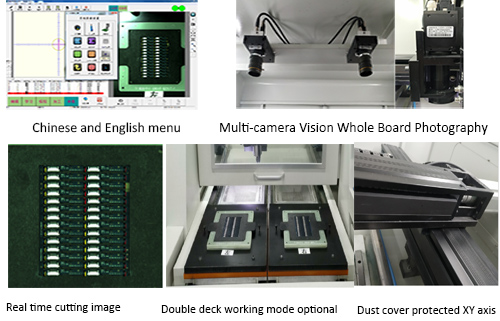

Automatic PCB router function:

Automatic PCB rounter is also called PCB cutting machine,with high speed spindle drying milling kit to cut high density PCBA and other material substrate.

JW-IR300C konforme deklaag genesingsoond:

| JW-IR300C konforme deklaag genesingsoond | JW-RM288 |

| Structure | Single spindle,dual work platforms |

| Machine dimension | 1000*1244*1400JW-IR300C konforme deklaag genesingsoond |

| Gewig | Approx.700kg |

| Vacuum power | 1HP/2.2KW |

| Vacuum weight | approx.130kg |

| JW-IR300C konforme deklaag genesingsoond | 3.5JW-IR300C konforme deklaag genesingsoond(3phrase) |

| Dust collection method | Bottom collection |

| Work table size | 300*400JW-IR300C konforme deklaag genesingsoond |

| Platform driving type | Double rotary platform,precision slicer with 3 phrase motor inverte |

| Drive system | X/Y/Z/Waxis driven by servo motor;W axis driven by three phrase motor frequency converter |

| Routing spindle | 5000~50000rpm,automatic cooling |

| Sny spoed | 1~100mm/s |

| Cutting accuracy | ±0.05mm |

| Repeat accuracy | ±0.02mm |

| Moving speed | 800mm/s |

| Z Axis system | screw driven,dual guide |

| Router kit | 0.8~3.0 left rotation,Shank Tungsten Steel |

| Tool life control | Software program control |

| Active protection function | Saftey light curtain |

| Security door | manual door |

| Abnormal alarm | Yes |

JW-IR300C konforme deklaag genesingsoond:

1.Fully electric control to ensure long-term operation accuracy of equipment.

2.360 degree 2 index rotation of the work surface to improve production efficiency.

3.Independent research and development control system, safe and stable upgrade.

4.Reasonable mechanical structure, small size and high cutting precision.

5.Service and parts supply in a timely manner to quickly solve production problems.

More about the machine:

Video link: https://youtu.be/0XeUUAQs2DY

saam met ondersteunende stelsel om PCB-vervormde tempo te verminder 2005,

saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder:saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,Taal,

saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,Taal,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder.

saam met ondersteunende stelsel om PCB-vervormde tempo te verminder,saam met ondersteunende stelsel om PCB-vervormde tempo te verminder;