- JW-608A automatyske PCB skonk cutter

- JW-608A automatyske PCB skonk cutter

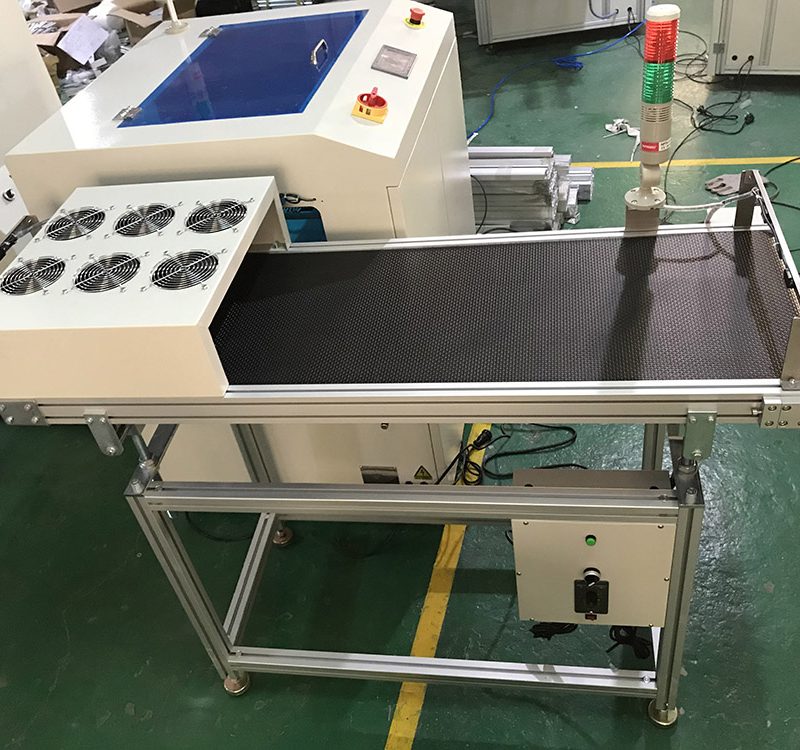

Reflow exit conveyor function

The reflow exit conveyor is used to transport PCB after reflow oven,which is specially made for clients according to their request.

Technyske spesifikaasje:

| Merk | Jwide |

| Model | JW-808H Reflow conveyor |

| Outer Dimension | 1500*550*1120JW-608A automatyske PCB skonk cutter |

| Conveyor height | 950+/-20JW-608A automatyske PCB skonk cutter |

| PCB Belt width | 408JW-608A automatyske PCB skonk cutter |

| Total machine width | 432JW-608A automatyske PCB skonk cutter |

| Conveyor length | 1.5M |

| Cooling fans quantity | 6pcs totally |

| Machine structure | aluminium frame |

| Rjochting | Left to Right; right to left |

| Foot switch | standert |

| cooling fans | quantity customerized |

| Alarm | Automatically when pcb reaches end of conveyor |

| JW-608A automatyske PCB skonk cutter | Black ESD High temperature |

| Kommunikaasje plug | SMEMA Signal plug for up&down line |

| JW-608A automatyske PCB skonk cutter | Approx.75Kg |

Product Details:

1.Conveyor Left to Right: Left Side Connects to Reflow Oven.

2.Height conveyor(from ground to belt): 950mm +/-20mm adjustable with Hand Crank

3.Standard high temperature belt is 60~70 degree Celsius

4.Extension on LEFT SIDE: 152.4JW-608A automatyske PCB skonk cutter (6 inches),Overall Height of Extension (Including Belt + Roller) is Approximately 25mm .

5. Sensors and Sound Alarm,Light Tower towards the end of conveyor

6.Once PCB reaches end of conveyor, Audible Alarm & Light Tower will turn on

7.Conveyor will move forward upon PCB exiting reflow

8.Conveyor stops when the board is out of the reflow

9.Stop/Go Configuration with Middle Sensor

Pictures: